How to check the quality of film coated plywood?

13/09/2021

Administrator

2692

Checking the quality of film-faced plywood is a very important before purchasing. Please refer to the article on main points of checking the quality of film-faced plywood:

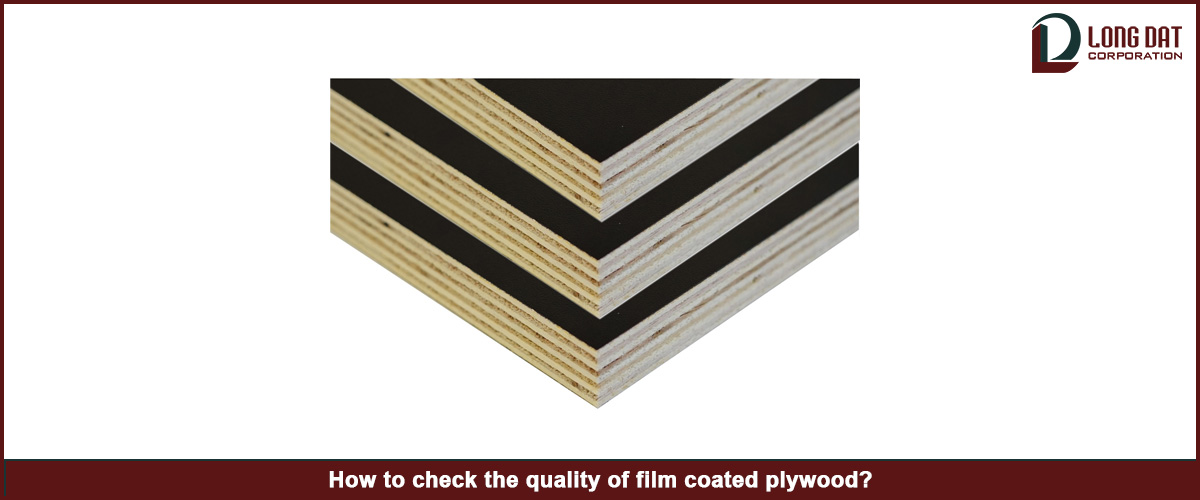

1. Surface appearance

The first impression of a product is usually the appearance of the surface. With film-faced plywood, surface quality also plays an important role in waterproofing, ensuring a smooth, beautiful concrete surface that meets the contractor's technical requirements.

To test the surface of film-faced plywood, we need to make sure that the surface must be smooth, flat, even. The face must not be burned, not broken, not punctured, few burrs. For the film burn points, it is necessary to look against the light direction to determine the position and the area, thereby deciding whether the goods are of good quality or not.

2. Glue

Glue is an ingredient that helps plywood bond and shape water resistance. The glue of filmfaced plywood is usually WBP. WBP ( stand for water boiled proof) is a common name for glues that are resistant to boiling water such as phenolic, melamine, ...

If WBP glue is used for plywood, when exposed to natural outdoor conditions, water, and moisture for a long time , the plywood will not delaminated.

To check the quality of film-coated formwork plywood, you just need to boil the chipboard in boiling water. After a long time, if the board still does not delamination, it means that it is coated with WBP glue. Normally, if plywood can withstand cooking time from at least 18-24 hours.

3. Core

Plywood core can be divided into multi grades in descending order of quality: AA, A+, A, B+, B, C+ and C. The better the core, the better the quality of the top layer, the flatter and pressed.

Cores of grades AA and A+, high cost, are often used for very high quality film-faced plywood. Grade A board is used for high quality film-faced plywood that can be matched the standards of European countries, USA and Canada.

For the majority of customers, boards of grades B+ and B meet the requirements because of their affordable prices and universal, acceptable quality.

The material for making plywood is from wood material such as eucalyptus, acacia, rubber, etc. These are industrial plants commonly grown in Vietnam, capable of providing huge volume raw materials for industrial production.

To check the quality of the film-faced plywood core, we need to cut the board into smaller pieces. The tighter and firmer, the higher the quality. Otherwise, if there are many holes, the board is likely to be layed up from small veneer layers, the quality is lower.

4. Density and weight

While checking the quality of film-faced plywood, the density and the weight are also important. Filmfaced plywood that matched the construction quality requirements, must have a density of 550-600kg/ton. The weight of each sheet will depend on the thickness. Therefore, we always pay attention to this parameter when we inspecting the quality.

The above is a summary of main points to check the quality of film-faced plywood. We hope to help you get more useful information for selecting film-faced plywood.

In addition, you can refer to the plywood products at Longdat directly on the website longdat.com. We are always ready to support and look forward to cooperating with you!

Copyright © 2021 - LONGDAT IMPORT - EXPORT AND PRODUCTION CORPORATION - All rights reserved. Design by i-web.vn