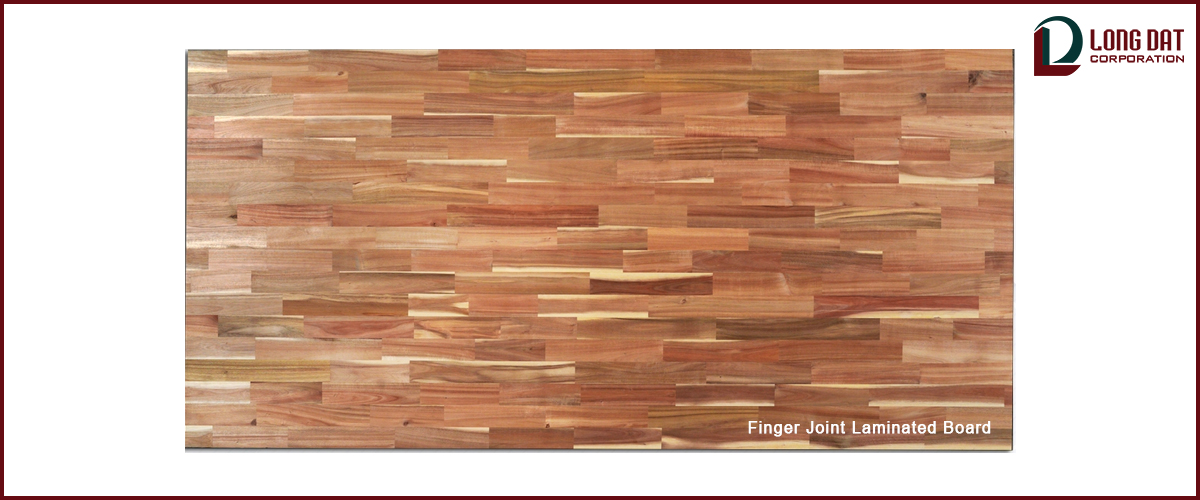

FINGER JOINT LAMINATED BOARD

Finger joint laminated board is an industrial wood product manufactured by joining small sized natural wood bars together with an adhesive under high pressure and temperature to form larger sized boards.

The small wooden slats are treated and dried strictly on modern lines to remove all harmful agents such as termites and mold. Then the wood is sawn, planed, milled, grafted, scrubbed, pressed, painted to create the finished product, which is a full-plate laminate.

.jpg)

1. Composition of finger joint laminated board

finger joint laminated board is composed of natural wood bars and adhesives such as Urea Formaldehyde (UF), Phenol Formaldehyde (PF) or Polyvinyl Acetate (PVAc) glue.

2. Advantages and disadvantages of finger joint laminated board

The specific advantages and disadvantages of finger joint laminated board are as follows:

2.1 Advantages of finger joint laminated board

The advantages of finger joint laminated board are inherited many of the advantages of natural wood, some of the outstanding advantages of laminated wood are as follows:

- No termites, warping

- Diverse in designs, the surface is well treated, so it has high color fastness, good scratch and impact resistance.

- Materials are mainly taken from planted forests, so it can solve the problem of scarcity of natural wood

- Durability is not inferior to solid wood if the processing level is good

- The price is 20-30% cheaper than solid natural wood

2.2 Disadvantages of finger joint laminated board

Besides the outstanding advantages, finger joint laminated board has some disadvantages such as in terms of aesthetics (with the vertical tenon), usually, the laminated wood planks are not used directly in the interior surfaces that are not used in the interior. pressed with veneer/HPL on the surface to increase aesthetics and use value. Therefore, the applications of this wood for furniture (in the form of panels) are still limited compared to other common industrial wood boards such as particle board, MDF board, HDF board, etc.

3. Production process and quality standards of laminated timber

finger joint laminated board has the following specific production processes and quality standards:

3.1 Manufacturing process of finger joint laminated board

The basic process of producing finger joint laminated board consists of the following steps:

Step 1: After being collected, the raw wood will undergo preliminary processing by the Ripsaw machine system, dividing the wood into standard bars.

Step 2: The wood is treated and dried to remove all agents that cause mold and termites

Step 3: Use a wood press to fasten the wooden slats together according to the pre-installed grafting pattern.

Step 4: After joining together into a large sheet, dry the glue to increase adhesion

Step 5: Add sanding blood to smooth the surface

Step 6: Process to create the finished product (covered with veneer, laminate or paint finish)

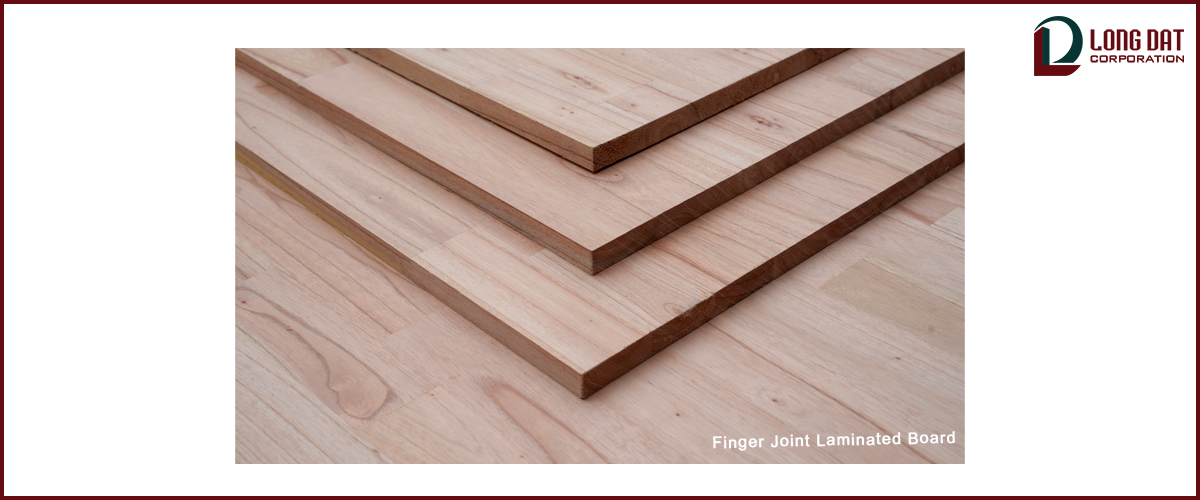

3.2 Quality standards of finger joint laminated board

AA quality: Is the best quality, suitable for the production of finished wood products that require absolute beauty. Double sides and beautiful edges, harmonious colors. That's why you don't need to spend a lot of time and effort to complete a product as you want without having to worry about the design, color and quality of the board.

Humidity: from 8 to 12% (maximum)

Glue : D4

AB quality: One side is beautiful, one side is relatively AB type, the beautiful side A absolutely does not allow dead eyes with black lines, and the B side allows dead eyes, small black eyes. Short and medium black lines. This item is suitable for the production of finished wood products such as: countertops, cabinet doors, kitchen cabinets...

Humidity: from 8 to 12% (maximum)

Glue : D4

AC quality: Face A is absolutely beautiful and doesn't allow dead eyes to black lines, and face C is not limited to lines or black eyes, color quality is relatively worse than the two above. G This type of board is used as a floor or wall board, only one side is beautiful.

Humidity: from 8 to 12% (maximum)

Glue : D4

BC quality: B side allows dead eyes, small black eyes, and C side does not limit lines or black eyes, color quality is relatively worse than the two above. This type of board is used as a core to cover veneer, as a frame for sofas, etc.

Humidity: from 8 to 12% (maximum)

Glue : D4

4. Application of finger joint laminated board

finger joint laminated board is now very commonly used in life, not only in Vietnam but also in many countries around the world. Some applications of laminated wood in various fields of life such as:

- Producing furniture for home, office, shop, showroom

- Interior design sales shop, showroom display

- Producing outdoor furniture with high resistance to mold, water, and termites

- Construction of wooden floors for homes and offices

- Decorative flooring

- Making bookshelves, decorative wooden shelves

- Homemade handicraft products

- Producing hall chairs, cinema chairs

- Make photo frames, picture frames, 3D carving or print pictures on wood

5. Prestigious place to supply finger joint laminated board

Long Dat Corp. is a reputable supplier of finger joint laminated board in the market today, with an international standard production process, good sales policy, and finger joint laminated board price in the market. We have been supplying plywood to more than 20 countries around the world, please contact us for detailed advice.

LongDat Import Export and Production Corporation

Address: No. 6, lane 95, Ho Tung Mau street, Tu Liem ward, Hanoi city.

Office: No. 6, lane 76/8, Duy Tan street, Tu Liem ward, Hanoi city.

Warehouse: Hamlet Bai, Dong Anh commune, Hanoi city.

Factory: Zone 9, Đông Thành commune, Phu Tho province.

Copyright © 2021 - LONGDAT IMPORT - EXPORT AND PRODUCTION CORPORATION - All rights reserved. Design by i-web.vn